By Edwin Neumann

Imagine a sleek, carbon fiber-encapsulated vehicle whizzing down a track with a top speed around 80 miles per hour. Rather than being powered by fuel, this aerodynamic vehicle is entirely human-powered and operated, its design allowing for maximum efficiency in converting the rider’s muscle power into kinetic energy. This is the end product of a year of designing, fabricating, and testing with the Human-Powered Vehicle Club (HPVC). Each May, teams from around the country meet to show off their innovative bikes and trikes at the Human-Powered Vehicle Challenge hosted by the American Society of Mechanical Engineers, which will be in Athens, Ohio this year. There, they are judged on a variety of categories such as speed, handling, safety, sustainability, and creativity.

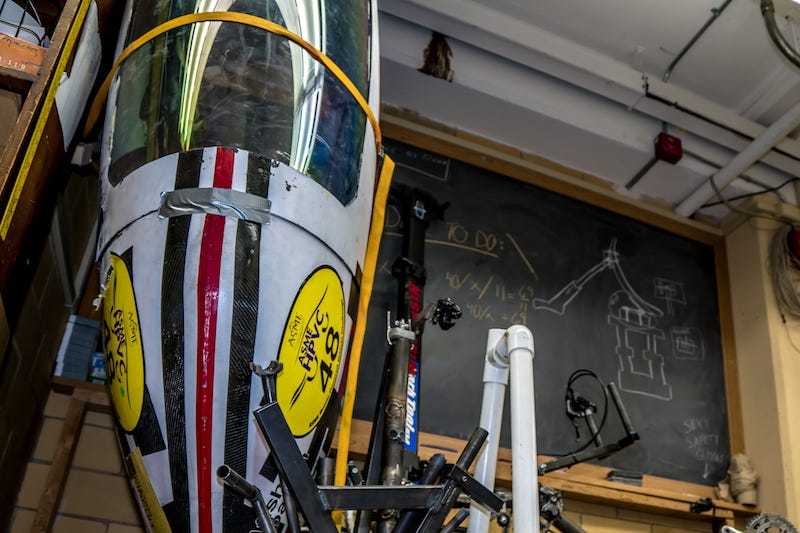

Leading HPVC at UW-Madison are President Karl Niendorf (junior) and Chief Engineer Luke Benish (senior), both majoring in mechanical engineering. The club was in the midst of its peak fabrication period earlier this semester. They kept busy in the Engineering Centers Building student shop, where the fairing (the outer casing of the vehicle) sub-team was working on creating a mold for casting the carbon-fiber fairing shell. Ordinarily this would be done with a machinable foam, but the team decided to take the more environmentally friendly (and tedious!) route by gluing scores of cardboard slabs together instead.

Several of the members in the shop were freshmen or new to the organization altogether, as Niendorf explained, “One thing that makes our team unique is the way new members can get involved.” Even those who have little or no prior experience can become active, contributing members since Benish holds seminars for those who want training in certain skills. “I try to make a point of including all the team members in the design and teaching them how to use different CAD and analysis programs,” Benish says. Everyone has the chance to work in the shop and obtain real machining know-how, which is instrumental when looking for internships or trying to stand out to potential employers. In fact, members will often be appointed to lead mini design projects, so there are components of the vehicle that are created by different people and integrated into the final product. “With a lot of teams, you have to be in [the club] for a year or two before you can really do much,” Niendorf says. “Here we really encourage new members to start right away by giving them a design project.” This is a valuable characteristic of the club that makes it such an asset to aspiring engineers.

The Human-Powered Vehicles Club at UW-Madison is completely run by students who come from all different disciplines. Naturally, the club attracts many mechanical engineers, but there are also biomedical engineers to deal with ergonomics, electrical engineers to wire the turn signals and brake lights, economics majors to handle sponsorship and funding, and essentially anyone who has a passion for bikes.

Being an engineering organization, the design process is virtually sacred. The group is broken up into four subgroups: fairing, frame, drive train, and innovation. The four teams come together at the weekly full team meetings to incorporate all their work and make a cohesive design. They are always looking for new ways to bring the team together and bond with events such as ice skating nights — this is a big part of building an efficient, high-performing team.

The club acts as a beneficial extracurricular supplement to the students’ classes, particularly those that teach the design process. “You’re not just hearing about the theory in the classroom, you’re applying it to the bike,” Niendorf says. One class in particular, Intro to Engineering 160, is deemed useful by both Niendorf and Benish. This is the class that most freshman engineers take, which includes a lab that allows students to create a product for a real client. “We follow almost the same skeleton as 160 throughout the design process,” Benish says. Together they brainstorm, design, test, and redesign all aspects of the vehicle to improve each year. Often, after coming up with several ideas, the small design projects for new members will deal with fabrication of pieces that could take alternative forms. By testing the different alternatives, the students can decide which is superior, such as concave versus convex wheel covers for the lowest drag coefficient. Testing plays a huge role in determining whether the vehicle meets the specifications of the annual competition. When the vehicle can reach average speeds of greater than 45 miles per hour, it becomes a necessity to achieve maximum safety for the operator. For a safety test, the team even brought their design to the Shell in order to utilize the Smith machine (equipment found in the weight room) to see how much weight it could bear with less than a centimeter and a half of deflection. If these tests prove to be unsatisfactory, then some parts of the project may warrant a redesign.

The theme for this year’s challenge is sustainability, so the group is focusing on efficiency and environmentally friendly materials. This boils down to simple choices such as using steel instead of aluminum and recycling old parts from previous years. The design is wrapped up in a comprehensive technical report, and it is then presented at the competition. Everyone in the club is given a voice in the design process, and all those who are active and contribute at least four hours of fabrication time in the shop each semester will be invited to the competition in Ohio. The team is nondiscriminatory, so the bike is prepared to adjust to people of different heights and weights. All members who want to ride the bike will have the opportunity, especially during the final testing stages before competing. This is a freshman-friendly organization, so anyone who likes hands-on experience and early leadership prospects is encouraged to check it out.

Good luck to our fellow Badgers in May. All are welcome to join the Human Powered Vehicles Club — just remember to wear a helmet!